A bearing is a machine element that supports another moving machine element known as a journal. It enables a relative motion between the contact surfaces of the members while carrying the load. While doing so a certain amount of power is wasted in overcoming frictional resistance due to the relative motion between the contact surfaces. We need to study the types of Bearings, design, and materials used for bearings briefly. In the previous article, we discussed the different types of Bearings. Hydrodynamic Lubricated Bearings are a type of bearing that comes under Sliding Contact Bearings. In this article, let us discuss the Hydrodynamic Lubricated Bearings in detail.

A little consideration will show that a certain amount of power is wasted in overcoming frictional resistance due to the relative motion between the contact surfaces. If the rubbing surfaces are in direct contact, there will be rapid wear. To reduce frictional resistance and wear and in some cases to carry away the heat generated, a layer of fluid known as lubricant may be provided. The lubricant used to separate the journal and bearing is usually a mineral oil refined from petroleum, but vegetable oils, silicon oils, greases, etc., may be used.

Hydrodynamic Lubricated Bearings

We have already discussed that in hydrodynamic lubricated bearings, there is a thick film of lubricant between the journal and the bearing. A little consideration will show that when the bearing is supplied with sufficient lubricant, pressure is built up in the clearance space when the journal is rotating about an axis that is eccentric with the bearing axis. The load can be supported by this fluid pressure without any actual contact between the journal and the bearing. The load-carrying ability of a hydrodynamic bearing arises simply because a viscous fluid resists being pushed around. Under the proper conditions, this resistance to motion will develop a pressure distribution in the lubricant film that can support a useful load.

The load-supporting pressure in hydrodynamic bearings arises from either

- The flow of a viscous fluid in a converging channel is known as wedge film lubrication.

- The resistance of a viscous fluid to being squeezed out from between approaching surfaces is known as squeeze film lubrication.

Assumptions in Hydrodynamic Lubricated Bearings

The following are the basic assumptions used in the theory of hydrodynamic lubricated bearings:

- The lubricant obeys Newton’s law of viscous flow.

- The pressure is assumed to be constant throughout the film thickness.

- The lubricant is assumed to be incompressible.

- The viscosity is assumed to be constant throughout the film.

- The flow is one-dimensional, i.e. the side leakage is neglected.

Important Factors for the Formation of Thick Oil Film in Hydrodynamic Lubricated Bearings

(For Illustration Purposes only)

According to Reynolds, the following factors are essential for the formation of a thick film of oil in hydrodynamic lubricated bearings:

- A continuous supply of oil.

- A relative motion between the two surfaces in a direction approximately tangential to the surfaces.

- The ability of one of the surfaces to take up a small inclination to the other surface in the direction of the relative motion.

- The line of action of resultant oil pressure must coincide with the line of action of the external load between the surfaces.

Wedge Film Journal Bearings

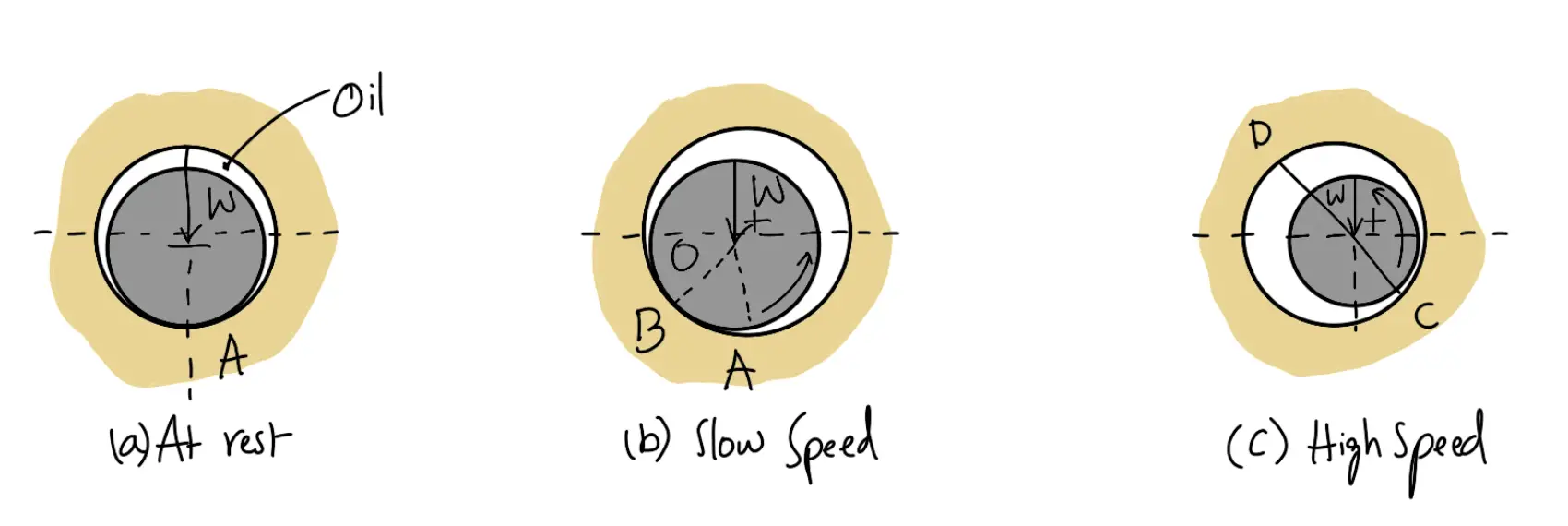

The load-carrying ability of a wedge-film journal bearing results when the journal and/or the bearing rotates relative to the load. The most common case is that of a steady load, a fixed (non-rotating) bearing, and a rotating journal. Figure (a) shows a journal at rest with metal-to-metal contact at A on the line of action of the supported load. When the journal rotates slowly in the anticlockwise direction, as shown in Figure (b), the point of contact will move to B, so that the angle AOB is the angle of sliding friction of the surfaces in contact at B. In the absence of a lubricant, there will be dry metal-to-metal friction. If a lubricant is present in the clearance space of the bearing and journal, then a thin absorbed film of the lubricant may partly separate the surface, but a continuous fluid film completely separating the surfaces will not exist because of slow speed.

When the speed of the journal is increased, a continuous fluid film is established as in the above figure (c). The center of the journal has moved so that the minimum film thickness is at C. It may be noted that from D to C in the direction of motion, the film is continually narrowing and hence is a converging film. The curved converging film may be considered as a wedge-shaped film of a slipper bearing wrapped around the journal.

Squeeze Film Journal Bearing

We have seen in the previous article that in a wedge film journal bearing, the bearing carries a steady load and the journal rotates relative to the bearing. But in certain cases, the bearings oscillate or rotate so slowly that the wedge film cannot provide a satisfactory film thickness. If the load is uniform or varying in magnitude while acting in a constant direction, this becomes a thin film or possibly a zero film problem. But if the load reverses its direction, the squeeze film may develop sufficient capacity to carry the dynamic loads without contact between the journal and the bearing. Such bearings are known as squeeze film journal bearings.

Terms used in Hydrodynamic Journal Bearing

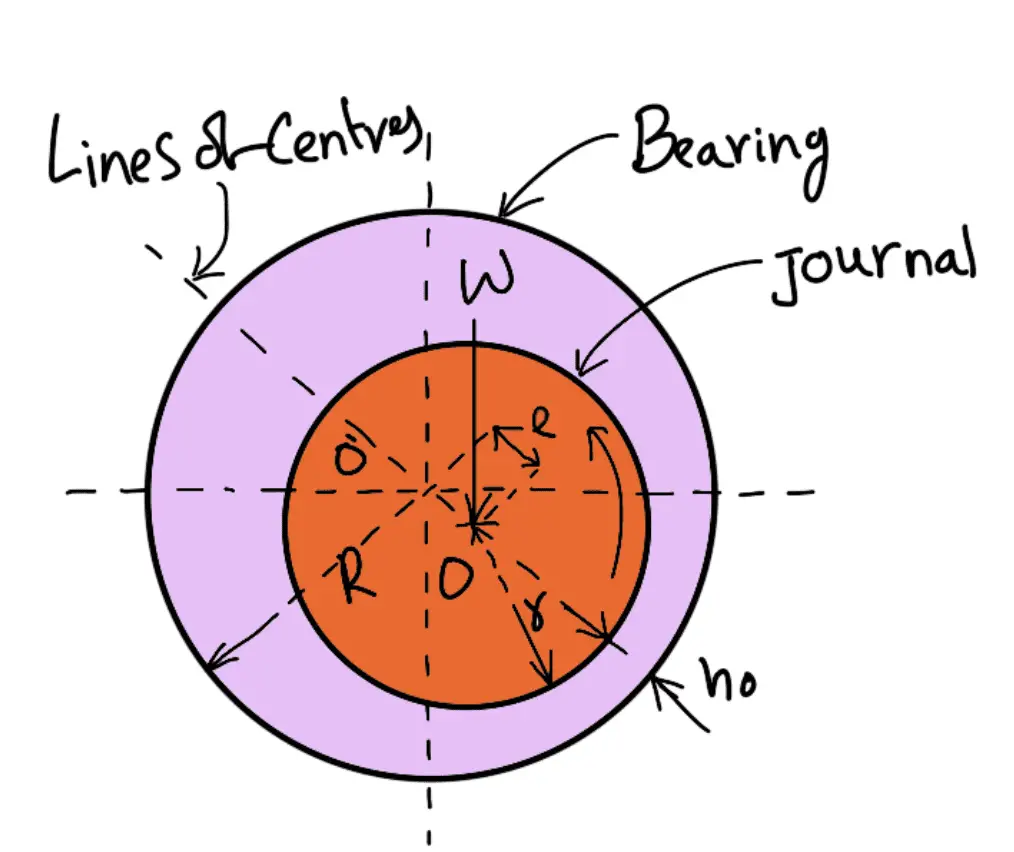

A hydrodynamic journal bearing is shown in the following figure, in which O is the center of the journal and O′ is the center of the bearing.

Let

D = Diameter of the bearing

d = Diameter of the journal

l = Length of the bearing

The following terms used in hydrodynamic journal bearing are important from the subject point of view:

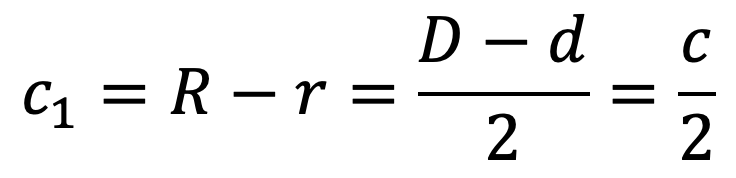

1. Diametral clearance: This is the difference between the diameters of the bearing and the journal. Mathematically, diametral clearance,

c = D – d

The diametral clearance (c) in a bearing should be small enough to produce the necessary velocity gradient so that the pressure built up will support the load. Also, the small clearance has the advantage of decreasing side leakage. However, the allowance must be made for manufacturing tolerances in the journal and bushing. A commonly used clearance in industrial machines is 0.025 mm per cm of journal diameter.

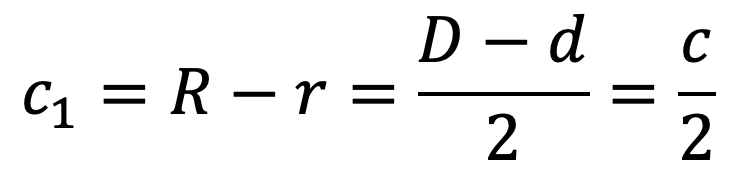

2. Radial clearance: It is the difference between the radii of the bearing and the journal. Mathematically, radial clearance,

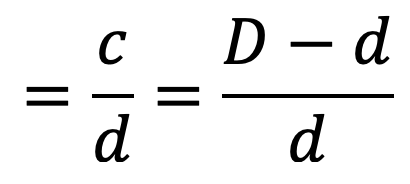

3. Diametral clearance ratio: This is the ratio of the diametral clearance to the diameter of the journal. Mathematically, the diametral clearance ratio

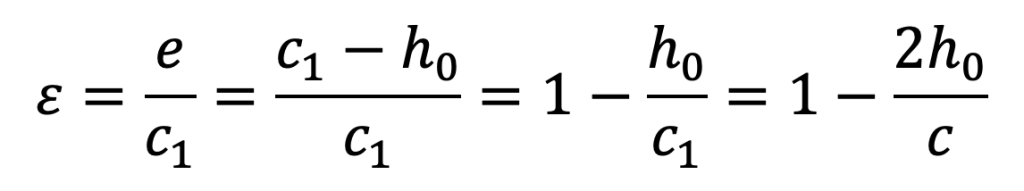

4. Eccentricity: It is the radial distance between the center (O) of the bearing and the displaced center (O′) of the bearing under load. It is denoted by e.

5. Minimum oil film thickness: It is the minimum distance between the bearing and the journal, under complete lubrication conditions. It is denoted by h0 and occurs at the line of centers as shown in the above figure. Its value may be assumed as c / 4.

6. Attitude or eccentricity ratio: It is the ratio of the eccentricity to the radial clearance. Mathematically, attitude or eccentricity ratio,

7. Short and long bearing: If the ratio of the length to the diameter of the journal (i.e. l / d) is less than 1, then the bearing is said to be short bearing. On the other hand, if l / d is greater than 1, then the bearing is known as a long bearing.

Important Notes:

- When the length of the journal (l ) is equal to the diameter of the journal (d ), then the bearing is called a square bearing.

- Because of the side leakage of the lubricant from the bearing, the pressure in the film is atmospheric at the ends of the bearing. The average pressure will be higher for a long bearing than for a short or square bearing. Therefore, from the standpoint of side leakage, a bearing with a large l / d ratio is preferable. However, space requirements, manufacturing, tolerances, and shaft deflections are better met with a short bearing. The value of l / d may be taken as 1 to 2 for general industrial machinery. In crankshaft bearings, the l / d ratio is frequently less than 1.