From Wikipedia, the free encyclopedia

Content deleted Content added

|

Tags: Mobile edit Mobile web edit Advanced mobile edit

|

|||

| Line 12: | Line 12: | ||

|

| regent1 = [[Lohara dynasty#Second Lohara dynasty|Udayānadeva]]<ref name=”govinda”>{{Cite book |last=Pillai |first=P. Govinda |url=https://books.google.com/books?id=sep5EAAAQBAJ&pg=PT150 |title=The Bhakti Movement: Renaissance or Revivalism? |date=2022-10-04 |publisher=Taylor & Francis |isbn=978-1-000-78039-0 |quote=Muslim rule was finally and firmly established in Kashmir by Shah Mir by deposing the last Hindu ruler, Kota Rani (1338-9). She was the widow of the last Hindu King of Kashmir, Udayana Deva (1323-38).|language=en}}</ref> |

| regent1 = [[Lohara dynasty#Second Lohara dynasty|Udayānadeva]]<ref name=”govinda”>{{Cite book |last=Pillai |first=P. Govinda |url=https://books.google.com/books?id=sep5EAAAQBAJ&pg=PT150 |title=The Bhakti Movement: Renaissance or Revivalism? |date=2022-10-04 |publisher=Taylor & Francis |isbn=978-1-000-78039-0 |quote=Muslim rule was finally and firmly established in Kashmir by Shah Mir by deposing the last Hindu ruler, Kota Rani (1338-9). She was the widow of the last Hindu King of Kashmir, Udayana Deva (1323-38).|language=en}}</ref> |

||

|

| reg-type1 = Monarch |

| reg-type1 = Monarch |

||

|

| succession = [[ |

| succession = [[ of |Kashmir]] |

||

|

| reign = 1338 − 1339<ref name=”govinda”/><ref name=”koul”>{{cite book|url=https://books.google.com/books?id=CW78DwAAQBAJ&pg=PA207|page=207|title=The Exiled Pandits of Kashmir: Will They Ever Return Home?|isbn=978-9811565373|year=2020|last1=Koul |first1=Bill K. }}</ref> |

| reign = 1338 − 1339<ref name=”govinda”/><ref name=”koul”>{{cite book|url=https://books.google.com/books?id=CW78DwAAQBAJ&pg=PA207|page=207|title=The Exiled Pandits of Kashmir: Will They Ever Return Home?|isbn=978-9811565373|year=2020|last1=Koul |first1=Bill K. }}</ref> |

||

|

| predecessor = [[Lohara dynasty#Second Lohara dynasty|Udayānadeva]] |

| predecessor = [[Lohara dynasty#Second Lohara dynasty|Udayānadeva]] |

||

|

| successor = Position abolished<br>[[Shah Mir]] (as [[List of monarchs of Kashmir|Sultan of Kashmir]]) |

| successor = Position abolished<br>[[Shah Mir]] (as [[List of monarchs of Kashmir|Sultan of Kashmir]]) |

||

|

| house = [[Lohara dynasty]] |

| house = [[Lohara dynasty]] |

||

|

| father = Rāmachandra |

| father = Rāmachandra |

||

Latest revision as of 13:32, 17 October 2024

Last Queen of Kashmir

Kota Rani (died 1344) was the last ruler of the Hindu Lohara dynasty in Kashmir. She was also the last female ruler of Kashmir. She was regent for her new husband because of the minority of her son in 1323−1338, and ruled as monarch in 1338−1339. She was deposed by Shah Mir, who became the second Muslim ruler of Kashmir after Rinchan who converted to Islam and ruled as Sultan Sadr-ud-din.

Kota Rani was the daughter of Ramachandra, the commander-in-chief of Suhadeva, the king of Lohara dynasty in Kashmir. Ramachandra had appointed an administrator, Rinchan, a Ladakhi. Rinchan became ambitious. He sent a force in the fort, in the guise of merchants, who took Ramachandra’s men by surprise. Ramachandra was killed and his family was taken prisoner.

To earn local support, Rinchan appointed Rawanchandra, the son of Ramachandra, as administrator of Lar and Ladakh, and married his sister Kota Rani.[5] He employed Shah Mir as a trusted courtier, who had entered Kashmir earlier and had been given an appointment in the government.[citation needed]

Rinchan converted to Islam and adopted the name of Sultan Sadruddin. He died as a result of an assassination after ruling for three years.[citation needed]

Kota Rani was first appointed as a regent for Rinchan’s young son. Later she was persuaded to marry Udayanadeva by the elders. [citation needed]

Udayanadeva became the ruler of Kashmir, but Kota Rani practically ruled the kingdom. After Udayanadeva died in 1338, Kota Rani became the ruler of Kashmir in her own right.[2]

Kota Rani had two sons. Rinchan’s son was under the charge of Shah Mir and Udayanadeva’s son was taught by Bhatta Bhikshana. Kota Rani appointed Bhatta Bhikshana as her prime minister.[citation needed]

Shah Mir pretended to be sick, and when Bhatta Bhikshana visited him, Shah Mir jumped out of his bed and killed him.[6] According to the historian Jonaraja, she committed suicide and offered her intestines to him as a wedding gift.[citation needed] According to the Kashmiri historian Jonaraja, Shah Mir killed both of her sons.

She was very intelligent and a great thinker. She saved the city of Srinagar from frequent floods by getting a canal constructed, named after her and called “Kute Kol”.[7] This canal gets water from Jhelum River at the entry point of city and again merges with Jhelum river beyond the city limits.[citation needed]

- Rakesh Kaul’s historical novel The Last Queen of Kashmir is based on Kota Rani’s life and legend.[8]

- In August 2019, Reliance Entertainment and Phantom Films announced that they would be making a movie on Kota Rani.[9][10]

- ^ a b Pillai, P. Govinda (4 October 2022). The Bhakti Movement: Renaissance or Revivalism?. Taylor & Francis. ISBN 978-1-000-78039-0.

Muslim rule was finally and firmly established in Kashmir by Shah Mir by deposing the last Hindu ruler, Kota Rani (1338-9). She was the widow of the last Hindu King of Kashmir, Udayana Deva (1323-38).

- ^ a b Koul, Bill K. (2020). The Exiled Pandits of Kashmir: Will They Ever Return Home?. p. 207. ISBN 978-9811565373.

- ^ “PSA dossier calls Mehbooba Mufti Kota Rani, Kashmir’s Hindu queen who ‘poisoned’ rivals”.

- ^ Culture and political history of Kashmir, Prithivi Nath Kaul Bamzai, M.D. Publications Pvt. Ltd., 1994.

- ^ “Queens, poets, academics, mystics: A calendar celebrates 12 inspirational women of Kashmir”.

- ^ Mihir Balantrapu, Kota, the fortress (Book review of The Last Queen of Kashmir), The Hindu, 5 August 2016.

- ^ “Kota Rani: Phantom Films to produce film on last Hindu queen of Kashmir. Details inside”. 27 August 2019.

- ^ “Madhu Mantena To Make Biopic On Kota Rani, Last Hindu Queen Of Kashmir”.

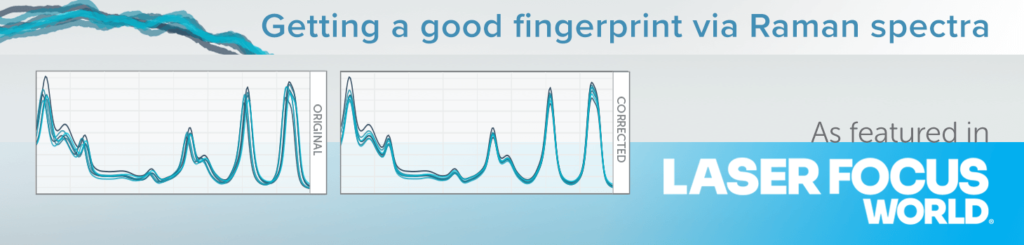

We are delighted to share that the January 2023 issue of Laser Focus World magazine will feature an article written by our own Cicely Rathmell, VP of Marketing, and Senior Staff Scientist, Dr. Dieter Bingemann. Getting a good fingerprint via Raman spectra details how variability in Raman spectra can be significantly reduced through good optical design and a few simple calibration measurements and corrections.

We are delighted to share that the January 2023 issue of Laser Focus World magazine will feature an article written by our own Cicely Rathmell, VP of Marketing, and Senior Staff Scientist, Dr. Dieter Bingemann. Getting a good fingerprint via Raman spectra details how variability in Raman spectra can be significantly reduced through good optical design and a few simple calibration measurements and corrections.