Gretchen Ertl

In brief

Promising new designs for both fission and fusion nuclear power reactors rely on molten salt to play key roles, such as transferring heat out to produce electricity and to keep important metal components cool. But a major concern is corrosion: Will the radiation inside a nuclear reactor speed up the rate at which the salt corrodes and weakens those metal components? MIT researchers have demonstrated that some metal alloys will corrode not more but less when they’re exposed to radiation under some conditions. The team devised and built an experimental setup that emulates conditions inside a molten salt–based nuclear reactor. Tests with various alloys show that certain combinations of elements become more resistant to corrosion when they are also subjected to radiation. The researchers provide simple guidelines for designers and operators to follow when selecting commercial alloys for their molten salt–based nuclear reactors.

Most discussions of how to avert climate change focus on solar and wind generation as key to the transition to a future carbon-free power system. But Michael Short, the Class of ’42 Associate Professor of Nuclear Science and Engineering and associate director of the Plasma Science and Fusion Center (PSFC), is impatient with such talk. “We can say we should have only wind and solar someday. But we don’t have the luxury of ‘someday’ anymore, so we can’t ignore other helpful ways to combat climate change,” he says. “To me, it’s an ‘all-hands-on-deck’ thing. Solar and wind are clearly a big part of the solution. But I think that nuclear power also has a critical role to play.”

For decades, researchers have been working on designs for both fission and fusion nuclear reactors using molten salts as fuels or coolants. While those designs promise significant safety and performance advantages, there’s a catch: Molten salt and the impurities within them often corrode metals, ultimately causing them to crack, weaken, and fail. Inside a reactor, key metal components will be exposed not only to molten salt but also simultaneously to radiation, which generally has a detrimental effect on materials, making them more brittle and prone to failure. Will irradiation make metal components inside a molten salt–cooled nuclear reactor corrode even more quickly?

Short and Dr. Weiyue Zhou PhD ’21, a postdoc in the PSFC, have been investigating that question for eight years. Their experimental findings show that certain alloys will corrode more slowly when they’re irradiated—and identifying them among all the available commercial alloys can be straightforward.

The first challenge—building a test facility

When Short and Zhou began investigating the effect of radiation on corrosion, practically no reliable facilities existed to look at the two effects at once. The standard approach was to examine such mechanisms in sequence: first corrode, then irradiate, then examine the impact on the material. That approach greatly simplifies the task for the researchers but with a major trade-off. “In a reactor, everything is going to be happening at the same time,” says Short. “If you separate the two processes, you’re not simulating a reactor; you’re doing some other experiment that’s not as relevant.”

So, Short and Zhou took on the challenge of designing and building an experimental setup that could do both at once. Short credits a team at the University of Michigan for paving the way by designing a device that could accomplish that feat in water rather than molten salts. Even so, Zhou notes, it took them three years to come up with a device that would work with molten salts. Both researchers recall failure after failure, but the persistent Zhou ultimately tried a totally new design, and it worked. Short adds that it also took them three years to precisely replicate the salt mixture used by industry—another factor critical to getting a meaningful result. The hardest part was achieving and ensuring that the purity was correct by removing critical impurities such as moisture, oxygen, and certain other metals.

As they were developing and testing their setup, Short and Zhou obtained initial results showing that proton irradiation did not always accelerate corrosion but sometimes actually decelerated it. They and others had hypothesized that possibility, but even so, they were surprised. “We thought we must be doing something wrong,” recalls Short. “Maybe we mixed up the samples or something.” But they subsequently made similar observations for a variety of conditions, increasing their confidence that their initial observations were not outliers.

The successful setup

Central to their approach is the use of accelerated protons to mimic the impact of the neutrons inside a nuclear reactor. Generating neutrons would be both impractical and prohibitively expensive, and the neutrons would make everything highly radioactive, posing health risks and requiring very long times for an irradiated sample to cool down enough to be examined. Using protons would enable Short and Zhou to examine radiation-altered corrosion both rapidly and safely.

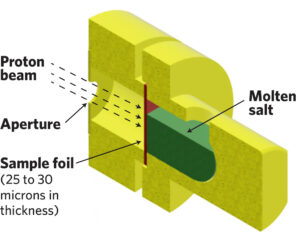

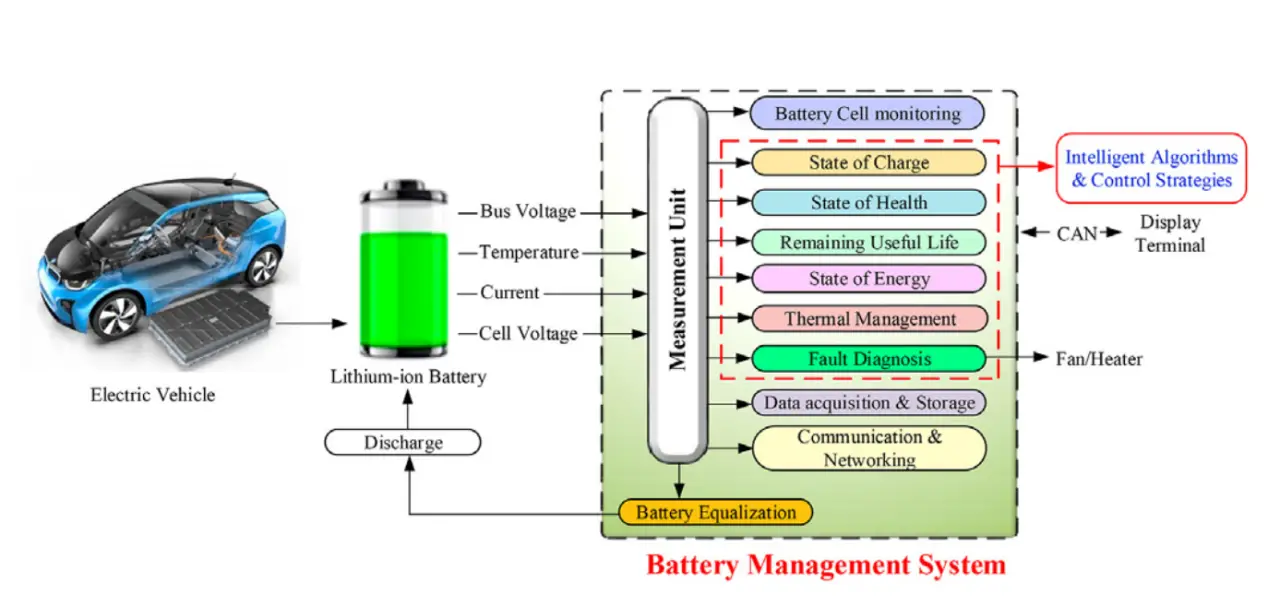

The researchers’ experimental setup. This diagram shows the key features of the setup that the researchers designed and built to explore the effect of radiation on corrosion inside a molten salt nuclear reactor. The test chamber appears in yellow. A thin sample of the alloy being tested (at the center, red) is suspended between a bath of molten salt (green) and a beam of protons coming from the other side (dashed lines). With this setup, a single foil sample can be exposed to molten salt over its entire surface and—at the same time—to radiation limited to a circle at its center. Experiments show that the impact of radiation on corrosion damage varies widely from alloy to alloy.

The final design for their experimental setup is illustrated in the diagram above. The test chamber is shown in yellow. The bath of molten salt is shown in green. The thin sheet of the metal alloy being tested is at the center (in red), and the beam of protons enters from the left (dashed lines). With this setup, a thin foil sample of the alloy being tested is exposed to molten salt on one side and bombarded with proton radiation on the other side, but the proton beam is restricted to a circle in the middle of the foil sample. “No one can argue with our results then,” says Short. “In a single experiment, the whole sample is subjected to corrosion, and only a circle in the center of the sample is simultaneously irradiated by protons. We can see the curvature of the proton beam outline in our results, so we know which region is which.”

The results with that arrangement were unchanged from the initial results. They confirmed the researchers’ preliminary findings, supporting their controversial hypothesis that rather than accelerating corrosion, radiation would actually decelerate corrosion in some materials under some conditions. Fortunately, they just happen to be the same conditions that will be experienced by metals in molten salt–cooled reactors.

Why is that outcome controversial? A closeup look at the corrosion process will explain. When salt corrodes metal, the salt finds atomic-level openings in the solid, seeps in, and dissolves salt-soluble atoms, pulling them out and leaving a gap in the material—a spot where the material is now weak. “Radiation adds energy to atoms, causing them to be ballistically knocked out of their positions and move very fast,” explains Short. So, it makes sense that irradiating a material would cause atoms to move into the salt more quickly, increasing the rate of corrosion. Yet in some of their tests, the researchers found the opposite to be true.

Experiments with “model” alloys

The researchers’ first experiments in their novel setup involved “model” alloys consisting of nickel and chromium, a simple combination that would give them a first look at the corrosion process in action. In addition, they added europium fluoride to the salt, a compound known to speed up corrosion. In our world, we often think of corrosion as taking years or decades, but in the more extreme conditions of a molten salt reactor it can noticeably occur in just hours. The researchers used the europium fluoride to speed up corrosion even more without changing the corrosion process. This allowed for more rapid determination of which materials, under which conditions, experienced more or less corrosion with simultaneous proton irradiation.

The use of protons to emulate neutron damage to materials meant that the experimental setup had to be carefully designed and the operating conditions carefully selected and controlled. Protons are hydrogen atoms with an electrical charge; and under some conditions, the hydrogen could chemically react with atoms in the sample foil, altering the corrosion response, or with ions in the salt, making the salt more corrosive. Therefore, the proton beam had to penetrate the foil sample but then stop in the salt as soon as possible. Under these conditions, the researchers found they could deliver a relatively uniform dose of radiation inside the foil layer while also minimizing chemical reactions in both the foil and the salt.

Tests showed that a proton beam accelerated to 3 million electron-volts combined with a foil sample between 25 and 30 microns thick would work well for their nickel-chromium alloys. The temperature and duration of the exposure could be adjusted based on the corrosion susceptibility of the specific materials being tested.

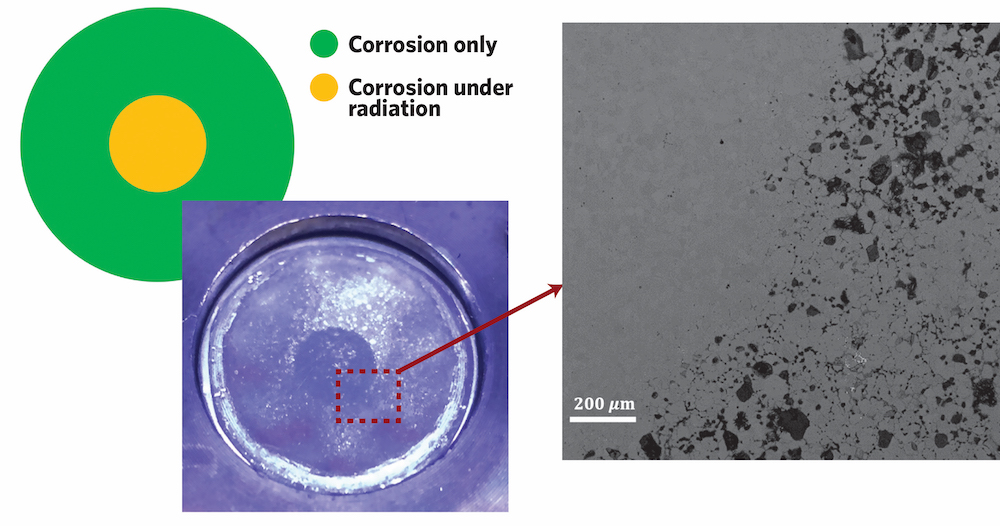

Experimental results with model compounds. This figure shows results from tests on a simple alloy consisting of just nickel and chromium. The blue image shows the side of the foil sample facing the proton beam. The whole sample was exposed to molten salt, while only the circle at the center was also subjected to the beam of protons. The boundary between the two areas is clear. The electron microscope image to the right focuses on the region inside the red rectangle. The area at the right in the image shows dark patches where the salt penetrated all the way through the foil, while the area on the left shows almost no such dark patches. The curvature marking the boundary between the damaged and less-damaged regions in the two images is the same, confirming that damage is less extreme where the sample was both corroded and irradiated.

The top figure above shows sample results. The blue image shows the side of the foil sample facing the proton beam. During the experiment, the entire sample was exposed to molten salt on the opposite side, and the circular region at the center was simultaneously bombarded with protons from this side. The difference in appearance is striking in this optical image. The electron microscope image at the right focuses on the region inside the red rectangle. The area at the right in the image shows dark patches where the salt penetrated all the way through the foil, while the area on the left shows almost no such dark patches. The curvature marking the outside of the radiation beam in the blue image matches the curvature between the damaged and less-damaged regions in the electron microscope image, validating the researchers’ experimental approach.

To confirm that the dark patches were due to corrosion, the researchers cut through the foil sample to create cross sections. In them, they could see tunnels that the salt had dug into the sample. “For regions not under radiation, we see that the salt tunnels link the one side of the sample to the other side,” says Zhou. “For regions under radiation, we see that the salt tunnels stop more or less halfway and rarely reach the other side. So we verified that they didn’t penetrate the whole way.”

The results “exceeded our wildest expectations,” says Short. “In every test we ran, the application of radiation slowed corrosion by a factor of 2 to 3 times.”

More experiments, more insights

Subsequent tests with the model alloys provided further insights. To more closely replicate commercially available molten salt, the researchers omitted the additive (europium fluoride) that they had used to speed up corrosion, and they tweaked the temperature for even more realistic conditions. “In carefully monitored tests, we found that by raising the temperature by 100 degrees Celsius, we could get corrosion to happen about 1,000 times faster than it would in a reactor,” says Short.

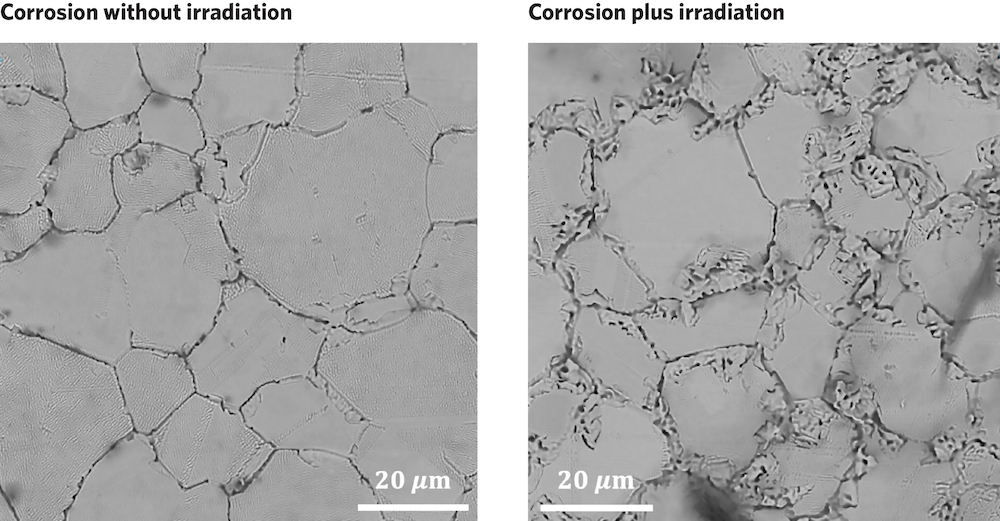

Images showing damage on the salt-facing side of a foil sample. These electron microscope images show the side of the foil of the nickel-chromium alloy sample facing the molten salt. The one on the left shows a section that was only exposed to the molten salt. The corrosion is clearly focused on the weakest part of the structure—the boundaries between the grains in the metal. The image on the right shows a section that was exposed to both the molten salt and the proton beam. Here the corrosion isn’t limited to the grain boundaries but is more spread out over the surface. Experimental results show that these cracks are shallower and less likely to cause a key component to break.

Sample results with the molten salt (without the corrosive additive) plus the nickel-chromium alloy appear in the figure above. These images show the salt-facing side of the sample, so the directly corroded side. The image on the left is from the corrosion-only region, while the one on the right is from the region that was also irradiated. The corrosion damage seen in the two regions is distinctly different.

Short explains the observations. Metals are made up of individual grains inside which atoms are lined up in an orderly fashion. Where the grains come together there are areas—called grain boundaries—where the atoms don’t line up as well. In the corrosion-only image on the left, dark lines track the grain boundaries. Molten salt has seeped into the grain boundaries and pulled out salt-soluble atoms. In the corrosion-plus-irradiation image on the right, the damage is more general. It’s not only the grain boundaries that get attacked but also regions within the grains.

So, when the material is irradiated, the molten salt also removes material from within the grains. Over time, more material comes out of the grains themselves than from the spaces between them. The removal isn’t focused on the grain boundaries; it’s spread out over the whole surface. As a result, any cracks that form are shallower and more spread out, and the material is less likely to fail.

Testing commercial alloys

The experiments described thus far involved model alloys—simple combinations of elements that are good for studying science but would never be used in a reactor. In the next series of experiments, the researchers focused on three commercially available alloys that are composed of nickel, chromium, iron, molybdenum, and other elements in various combinations.

Results from the experiments with the commercial alloys showed a consistent pattern—one that confirmed an idea that the researchers had going in: The higher the concentration of salt-soluble elements in the alloy, the worse the radiation-induced corrosion damage. Radiation will increase the rate at which salt-soluble atoms such as chromium leave the grain boundaries, hastening the corrosion process. However, if there are more not-soluble elements such as nickel present, those atoms will go into the salt more slowly. Over time, they’ll accumulate at the grain boundary and form a protective coating that blocks the grain boundary—a “self-healing mechanism that decelerates the rate of corrosion,” say the researchers.

Thus, if an alloy consists mostly of atoms that don’t dissolve in molten salt, irradiation will cause them to form a protective coating that slows the corrosion process. But if an alloy consists mostly of atoms that dissolve in molten salt, irradiation will make them dissolve faster, speeding up corrosion. As Short summarizes, “In terms of corrosion, irradiation makes a good alloy better and a bad alloy worse.”

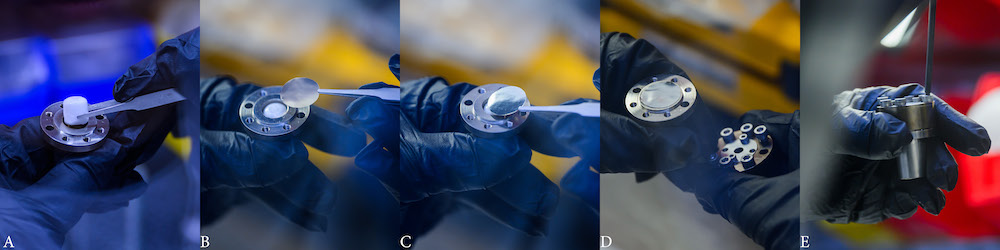

Steps involved in setting up the test chamber for an experiment with the proton accelerator. A. Working inside a glove box, postdoc Weiyue Zhou first drops in a pellet of salt—the key to emulating the corrosive environment inside a molten salt–based nuclear reactor. B, C. Next, he places a sample of the metal being tested on the top of the test chamber, where it will be exposed to the salt pellet beneath it. The metal sample is a foil disc about 21 millimeters in diameter and just 25 to 30 microns thick. D. Here, Zhou prepares to put the top on the test chamber. E. And here he screws on the top, sealing it shut. The test chamber is now ready to be mounted on the proton accelerator. With this setup, the researchers expose the whole foil sample to the corrosive salt, and—by shielding part of it from the incoming protons—they also subject a limited but well-defined section of it to the proton beam at the same time. Credit: Gretchen Ertl

Real-world relevance plus practical guidelines

Short and Zhou find their results encouraging. In a nuclear reactor made of “good” alloys, the slowdown in corrosion will probably be even more pronounced than what they observed in their proton-based experiments because the neutrons that inflict the damage won’t chemically react with the salt to make it more corrosive. As a result, reactor designers could push the envelope more in their operating conditions, allowing them to get more power out of the same nuclear plant without compromising on safety.

However, the researchers stress that there’s much work to be done. Many more projects are needed to explore and understand the exact corrosion mechanism in specific alloys under different irradiation conditions. In addition, their findings need to be replicated by groups at other institutions using their own facilities. “What needs to happen now is for other labs to build their own facilities and start verifying whether they get the same results as we did,” says Short. To that end, Short and Zhou have made the details of their experimental setup and all of their data freely available online. “We’ve also been actively communicating with researchers at other institutions who have contacted us,” adds Zhou. “When they’re planning to visit, we offer to show them demonstration experiments while they’re here.”

But already their findings provide practical guidance for other researchers and equipment designers. For example, the standard way to quantify corrosion damage is by “mass loss,” a measure of how much weight the material has lost. But Short and Zhou consider mass loss a flawed measure of corrosion in molten salts. “If you’re a nuclear plant operator, you usually care whether your structural components are going to break,” says Short. “Our experiments show that radiation can change how deep the cracks are, when all other things are held constant. The deeper the cracks, the more likely a structural component is to break, leading to a reactor failure.”

In addition, the researchers offer a simple rule for identifying good metal alloys for structural components in molten salt reactors. Manufacturers provide extensive lists of available alloys with different compositions, microstructures, and additives. Faced with a list of options for critical structures, the designer of a new nuclear fission or fusion reactor can simply examine the composition of each alloy being offered. The one with the highest content of corrosion-resistant elements such as nickel will be the best choice. Inside a nuclear reactor, that alloy should respond to a bombardment of radiation not by corroding more rapidly but by forming a protective layer that helps block the corrosion process. “That may seem like a trivial result, but the exact threshold where radiation decelerates corrosion depends on the salt chemistry, the density of neutrons in the reactor, their energies, and a few other factors,” says Short. “Therefore, the complete guidelines are a bit more complicated. But they’re presented in a straightforward way that users can understand and utilize to make a good choice for the molten salt–based reactor they’re designing.”

This research was funded by Eni S.p.A. through the MIT Plasma Science and Fusion Center’s Laboratory for Innovative Fusion Technologies. Earlier work was funded by the Transatomic Power Corporation and by the U.S. Department of Energy Nuclear Energy University Program. Equipment development and testing was supported by the Transatomic Power Corporation. For other funding sources and additional information about the research, please see the following:

AlMousa, W. Zhou, K.B. Woller, and M.P. Short. “Effects of simultaneous proton irradiation on the corrosion of commercial alloys in molten fluoride salt.” Corrosion Science, June 2023. Online: doi.org/10.1016/j.corsci.2023.111154.

Zhou, K.B. Woller, G. (T.) Zheng, P.W. Stahle, and M.P. Short. “A simultaneous corrosion/irradiation facility for testing molten salt-facing materials.” Nuclear Instruments and Methods in Physics Research Section B: Beam Interactions with Materials and Atoms, December 4, 2018. Online: doi.org/10.1016/j.nimb.2018.11.024.

Zhou, Y. Yang, G. Zheng, K.B. Woller, P.W. Stahle, A.M. Minor, and M.P. Short. “Proton irradiation-decelerated intergranular corrosion of Ni-Cr alloys in molten salt.” Nature Communications, July 2020. Online: doi.org/10.1038/s41467-020-17244-y.

This article appears in the Winter 2024 issue of Energy Futures.

The highly anticipated annual event, where the new Nextcorps/Luminate cohort of entrepreneurs present their technical issues to New York Photonics companies.

The highly anticipated annual event, where the new Nextcorps/Luminate cohort of entrepreneurs present their technical issues to New York Photonics companies.