In this article, you will learn What is a Lathe Machine? How does a lathe machine work? What is its main working principle? What are the main parts of a generic lathe machine? And also you will get information about the applications, significant operations and advantages and disadvantages of this machine.

Before we start further, I would like to tell you that the lathe machine is one of the oldest production machines. This machine is capable of making parts for almost every type of machine. That’s why this machine is called the Mother of all machines. In the previous article, we read about CNC Machines and CNC programming. CNC machines are advanced lathe machines that a computer can control. In sequence, it is also mandatory to know the primary lathe machine when you learn about CNC machines.

What is Lathe Machine?

The modern era can be considered the beginning of the era of lathe machines. Many other modern machines and parts have been made possible through the lathe machine. It is the most versatile and wide most usable machine in the world. This machine is widely used for woodwork and the machining of metal products. A lathe machine is to remove material from a job and converts the job into the required size and shape.

History and evolution of Lathe:

In the very beginning, the lathe was operated by two persons. That was used for woodwork. One person used to spin the wood with the help of a rope, while the other person used to shape that wooden workpiece with the help of a sharp tool. For this reason, it was called a double-person lathe. Further, Ancient Romans improved this machine by adding a turning bow and a paddle. A paddle was used to turn the workpiece. That made easiness for lathe operations. It looked like a manual sewing machine. And these types of lathes were known as “Spring Pole” lathes and were used in woodwork. You can see an example of a Spring pole lathe below the video.

After evolution, steam engines and water wheels were added to turn the workpieces at higher rpm. Adding electric motors to rotate the Chuck added a new chapter in industrial revolution history. And according to time machining precision, and operation time also improved. We will read different categories of lathe machines in our next article.

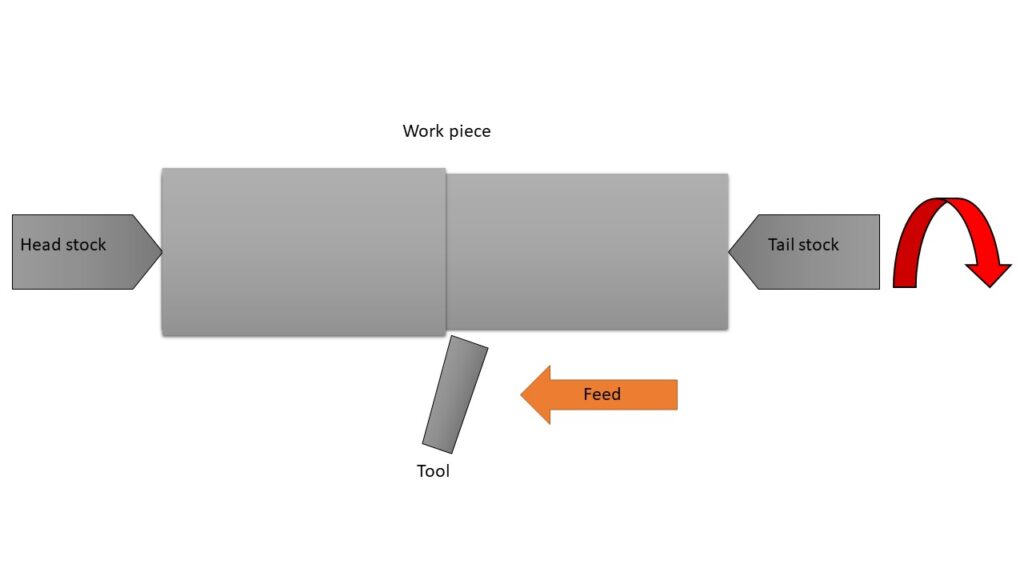

What is the working principle of a Lathe Machine?

These days lathe machine is the most popular and essential machinery in metalworking. LATHE is an abbreviation of “Longitudinal Access Turning Horizontal Equipment”. Lathes are intended to spin a workpiece against a tool bit, unlike milling machines. According to the complete form, it works on the principle of the rotating workpiece and fixed cutting tool. The workpiece is held between two strong supports known as centers.

Usually, lathes have two types of centers, A live center and another one is dead center. The Center, at the headstock, is called a live center. That rotates the workpiece. And dead center at the tailstock holds the workpiece aligned with the live center.

The cutting tool is moved towards the rotating workpiece, to cut it into the desired shape. For normal operations, the cutting tool is fed either parallel or perpendicular to the working axis. To understand the cutting tool, respective angles and working principle, please read about single point cutting tool.

What are the main parts of a Lathe Machine?

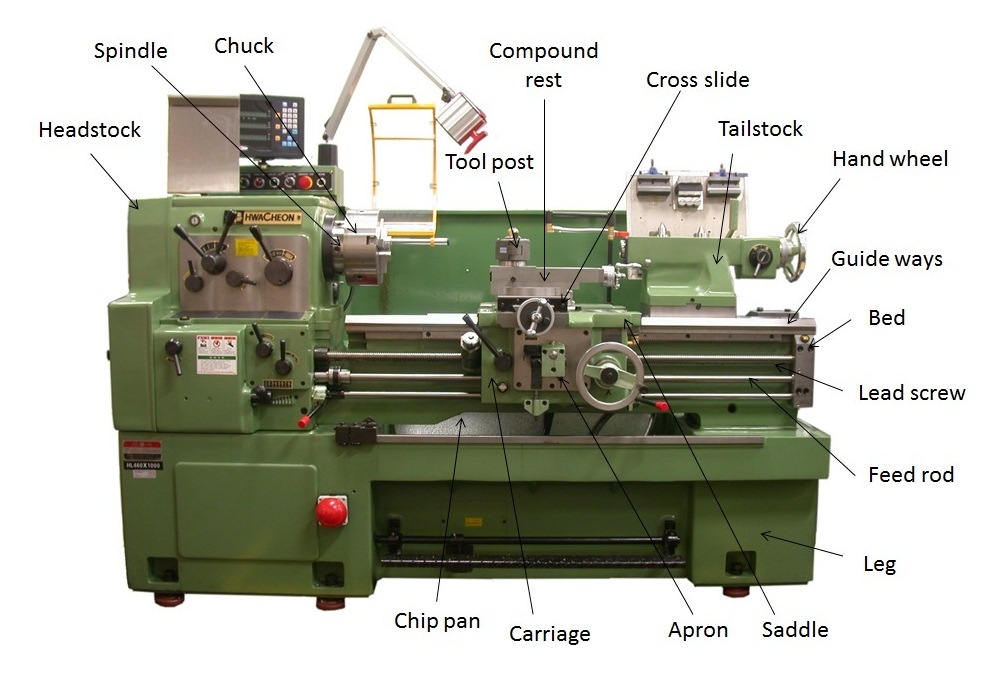

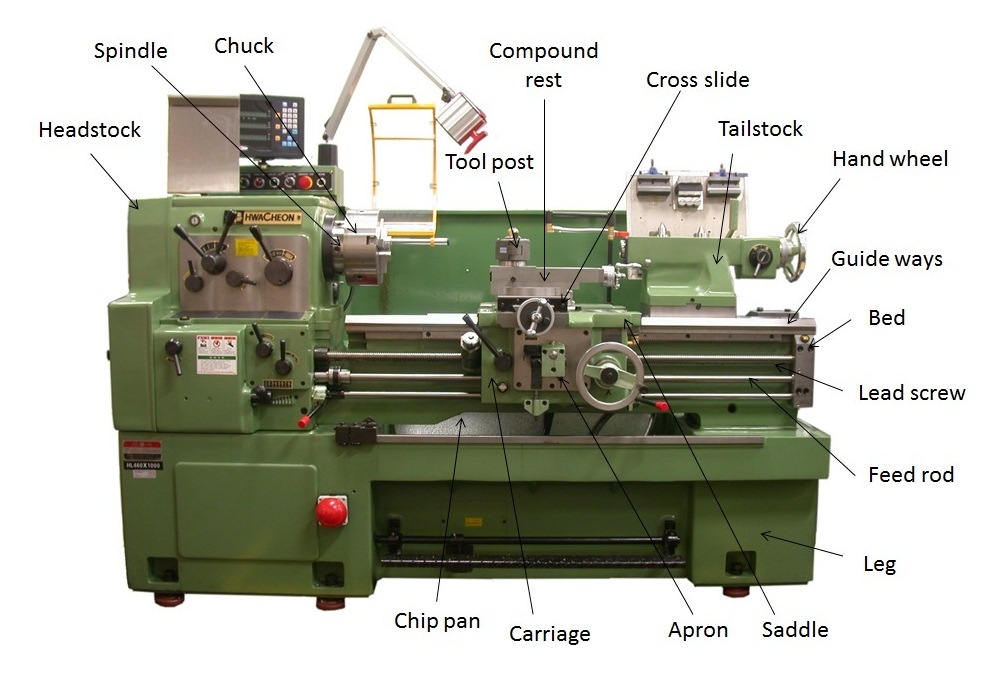

Construction of Lathe Machine: The main parts of the lathe machine are the bed, head stock, tail stock, tool post, leg, carriage, quick changing gearbox and etc. Let, we will discuss all parts in detail.

1. Leg:

The legs carry the whole weight of the lathe machine. And these convey the weight to the ground. The foundation bolts hold the legs rigidly. Legs are made of cast iron. Cast iron has a very high damping capacity. And it can handle higher compressive loads and is more vibration-resistant.

2. Bed:

A lathe machine bed is a horizontal part that carries a headstock, tailstock, and carriage. The bed is also made of cast iron (chilled cast iron), but in single-piece casting. Also, it is a heavier and more rugged part of the lathe. Legs support the bed. And it is made up of two heavy metal slides that run longitudinally, have ways or ‘V’s created on them, and are tightly supported by cross girths. The bed consists of two heavy steel slides parallel to its length. Slides are in a V-shaped cross-section and rigidly supported with girths.

3. Head Stock:

The headstock transmits power to the other parts of the lathe. It conveys power from the gearbox to the headstock spindle. The headstock spindle is a hollow shaft that rotates the chuck, and work can be attached. Headstock casting provides housing for driving pulleys, back gears, feed speed gears, a live center, and a headstock spindle. The headstock is mounted on the left-hand side of the machine bed.

4. Gearbox:

The gearbox is placed under the headstock. It contains gears with different sizes. These gears help to turn the chuck at various speeds and provide the required torque for operations. Modern lathe machines have quick-changing gearboxes.

5. Tail Stock:

The tail stock is mounted on the opposite side, at the end of the machine bed. Commonly, it is used to provide additional support for the longer part. Tail stock can be easily adjusted to align or non-align with respect to the live center. It carries a center, called the dead center. It plays a significant role when performing a heavy and oversized operation.

6. Carriage:

The outer guideways on the bed carry the carriage. And it can move in a parallel direction to the spindle axis. The carriage comprises of important parts like an apron, cross-slide, compound rest, saddle and tool-post.

An apron is the lower portion of the carriage. There are gears to make the apron mechanism, for adjusting the feed direction using the clutch mechanism and a split half nut for the automatic feed.

The cross slide is mounted on the carriage. Cross-slide travels in the perpendicular direction of the working axis. This member makes able to move the carriage in a perpendicular direction to the working axis.

The saddle is mounted on the cross-slide. In the saddle, the compound rest is adjustable to spin and fix to any desired angle.

The compound rest has a tool post, that holds the tool holder. All of these components of carriage allow the maximum degree of freedom to the tool. And this freedom allows for various types of lathe operations. Now, let’s will list out the Basic operations on a lathe machine.

Also Read:

Basic Operations on a Lathe Machine:

On a lathe machine, various operations can be performed accurately and with efficiency. The following operations are basic operations, that can be performed on an engine lathe.

1. Turning –

A. Straight Turning

B. Taper Turning

C. Shoulder Turning

2. Facing

3. Drilling

4. Chamfering

5. Threading

A. Internal Threading

B. External Threading

6. Under Cutting

7. Knurling

8. Grooving

9. Forming

10. Grinding and Polishing

11. Boring

A. Taper Boring

B. Counter Boring

Conclusion:

Now, you are familiar with the lathe machine, its history and its revolution. Also, you got an idea about its working principle and main parts. It is usually a good idea to become acquainted with the workshop lathe machine. That can help to understand the manufacturing process. In our next article, we will discuss about the basic lathe operations in detail.

If you like this article, please spread it in your connections.