Hydrometer, principle, components, types, uses

Hydrometer, principle, components, types, uses

Hydrometer, principle, components, types, uses

What is hydrometer?

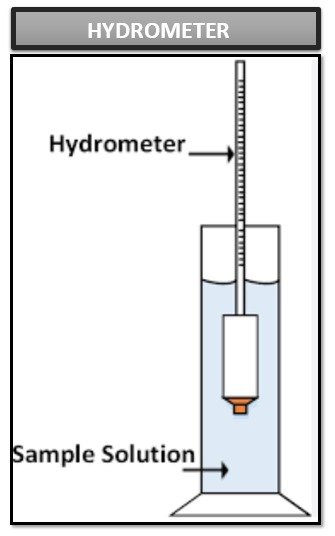

A hydrometer is a tool used in science to calculate a liquid's specific gravity (relative density). It consists of a cylindrical glass tube with a weighted pear on the bottom and a graduation on the stem. The stock is filled with lead or mercury shot for stability and the stem is marked with a series of calibrated markings.

The specific gravity of a liquid refers to its density relative to that of water. Pure water has a specific gravity of 1000 at a certain temperature, typically 20 degrees Celsius (68 degrees Fahrenheit). A hydrometer measures specific gravity by floating in a liquid, and the higher the specific gravity of the liquid, the deeper the hydrometer sinks.

Working principle:

The hydrometer works on the principle of buoyancy. When a hydrometer is placed in a liquid, it displaces a certain volume of that liquid. The displaced fluid exerts an upward force on the hydrometer, known as the buoyancy force, which opposes the weight of the hydrometer.

The magnitude of the buoyancy force is directly proportional to the volume of fluid displaced by the hydrometer. Simply put, the more fluid the hydrometer displaces, the greater the buoyancy force it experiences.

The design of the hydrometer ensures that the weight of the hydrometer is concentrated on the bottom, usually in the form of a weighted balloon filled with lead shot or mercury. This weight causes the hydrometer to partially sink into the liquid, leaving part of the bar above the surface.

The stem of the hydrometer is calibrated to a graduated scale. As the hydrometer sinks deeper into the higher specific gravity liquid, more of the stem sinks. Conversely, in a liquid with a lower specific gravity, the hydrometer floats higher, revealing more of the bar above the liquid's surface.

The specific gravity or relative density of the liquid is determined by the readings of the scale at the intersection of the liquid level and the rod. This measurement provides a quantitative measure of the density of a liquid in relation to water.

It is important to note that hydrometer specific gravity readings must be corrected for temperature fluctuations because the specific gravity of liquids changes with temperature. Most hydrometers are calibrated to a specific reference temperature, usually 20 degrees Celsius (68 degrees Fahrenheit), and it may be necessary to apply correction factors to the readings to account for temperature differences.

Components:

A hydrometer usually consists of the following parts:

Glass housing:

The main body of a hydrometer is usually made of glass. It is cylindrical in shape and has a hollow rod attached to it.

Weighted Bulb:

There is a weighted bulb on the bottom of the hydrometer. This lamp is filled with heavy material such as lead shot or mercury. The weight of the flask helps to partially submerge the hydrometer in the liquid to be tested.

Stem:

The stem is a long, thin tube that rides over a weighted bulb and connects to the main body of the hydrometer. A scale has been applied to the rod with which you can measure the specific gravity.

Calibration Marks:

The stem of the hydrometer has calibration marks or lines along its entire length. These tags are usually labeled with specific gravity or other relevant measurements. They enable the user to read and interpret the specific gravity of the liquid under test.

Meniscus:

The top surface of a liquid forms a curved shape known as the meniscus. When taking a reading, the user must align the meniscus with the calibration marks to get an accurate reading.

Temperature corrections:

Some hydrometers may have additional components or markings to allow for temperature corrections. These corrections are necessary because the specific gravity of liquids depends on the temperature. Temperature corrections ensure accurate readings by compensating for temperature effects on the liquid being measured.

It should be noted that there can be variations in the design of hydrometers depending on their specific application. Different industries may have hydrometers designed to measure certain parameters or fluids, such as alcohol content, sugar concentration, or electrolyte density in a battery.

Types:

There are different types of hydrometers, each designed for a specific application. Here are some common types:

Conventional hydrometer:

This is the standard type of hydrometer used for general gravity measurements. It usually has a wide range of specific gravity and is suitable for various liquids.

Baume Hydrometer:

Baume hydrometers are used to measure the specific gravity of liquids, especially solutions with a high sugar content or various industrial fluids. Commonly used in the food and beverage industry, they have two scales, one for liquids lighter than water and one for liquids heavier than water.

Proof and Tralle hydrometer:

This type of hydrometer is specifically designed to measure the alcohol content of distillates. Use a scale known as a "proof" or "trall" to indicate alcohol content. Test hydrometers are commonly used in the beverage industry and by regulators to determine the strength of alcoholic beverages.

Battery Hydrometer:

Battery hydrometers are used to measure the specific gravity of battery electrolytes in lead-acid batteries. They help evaluate the state of charge and overall health of the battery. Cordless hydrometers are commonly used in automotive, marine, and other applications where lead-acid batteries are used.

Soil Hydrometer:

Soil hydrometers are specifically designed to determine the particle size distribution of soil samples. They are used in geotechnical and agricultural applications to evaluate soil composition and properties.

API Hydrometer:

American Petroleum Institute (API) hydrometers are used to measure the specific gravity of petroleum products such as gasoline, diesel and crude oil. They are widely used in the oil and gas industry for quality control and product classification.

These are just a few examples of hydrometers commonly used in various industries. There are other specialized types of hydrometers designed for specific applications, such as winemaking and fermentation hydrometers, antifreeze checks, etc.

How to use a hydrometer:

Pour the liquid sample into the hydrometer jar.

Place the hydrometer in the jar and shake it quickly to remove any air bubbles.

Once the hydrometer has settled, read the scale at the lowest level of the liquid surface. (Most liquids stick to the sides of the can a bit, giving the surface a slight downward curve called the meniscus.)

Determine the temperature of the sample. If the temperature deviates from the temperature of the hydrometer solution, use the instrument manufacturer's temperature correction table to correct the reading. Many hydrometers are calibrated at a solution temperature of 15°C or 60°F.

Improved accuracy:

Accuracy depends on three main factors:

1)Cleaning:

The hydrometer, hydrometer tray and reading fluid should be properly cleaned. The surface of the hydrometer and stem is particularly important so that the liquid can rise evenly and fuse on the stem to form an almost invisible film.

2)Temperature:

The hydrometer and liquid should be the same temperature as the surrounding atmosphere. This prevents the density from changing during the test.

3)Proper immersion:

The inner diameter of the hydrometer should be approximately 25 mm larger than the outer diameter of the hydrometer. The vessel should also be at least an inch above the hydrometer.

Uses:

Hydrometers have a wide variety of applications in various industries. Here are some common uses for hydrometers:

Brewing and winemaking:

Hydrometers are widely used in the beer and wine industry to measure the specific gravity of wort and wine during fermentation. By tracking changes in specific gravity over time, brewers and winemakers can track the progress of fermentation, assess alcohol content, and determine when fermentation is complete.

Automotive and Battery Industry:

Battery hydrometers are used to measure the specific gravity of lead-acid battery electrolytes. By measuring the specific gravity, it is possible to assess the state of charge and the general condition of the battery. This will help determine if the battery needs to be charged, repaired or replaced.

Distillate Production:

Proof and Tralle hydrometers are used to measure the alcohol content of distillates. This is critical for distilleries to ensure they are producing spirits of the desired strength and comply with legal requirements.

Petrochemical Industry:

API hydrometers are commonly used in the petrochemical industry to measure the specific gravity of petroleum products. It helps with quality control, product classification and density determination of various fuels, oils and lubricants.

Agriculture and soil analysis:

Soil hydrometers are used in agriculture and geotechnical engineering to determine the particle size distribution of soil samples. This information is necessary to evaluate soil fertility, drainage characteristics and suitability for specific crops.

Antifreeze and coolant testing:

Hydrometers are used to measure the specific gravity of antifreeze and coolant solutions in the automotive industry. This helps determine the concentration of the solution, ensuring proper cooling and frost protection of the motors.

Industrial and laboratory applications:

Hydrometers are used in various laboratory and industrial settings to measure the specific gravity of liquids such as chemicals, solvents and industrial fluids. This information is essential for quality control, process monitoring and product stability.

These are just a few examples of the many applications of hydrometers. Hydrometers are versatile instruments used in many industries where specific gravity or density measurements are required for process control, product quality assessment and research purposes.

What's Your Reaction?