Vernier caliper

Vernier caliper

What is Caliper?

It is a precision measuring instrument used to accurately measure the length, diameter, thickness, and depth of various objects. It includes a main scale and a sliding vernier scale, ensuring high reading accuracy.

Who Developed the Caliper:

The machine was developed in the 17th century by Pierre Vernier, a French mathematician and inventor. He introduced the Vernier scale, a secondary scale that allowed for more precise measurements with calipers. The caliper is a popular measuring tool still in use today.

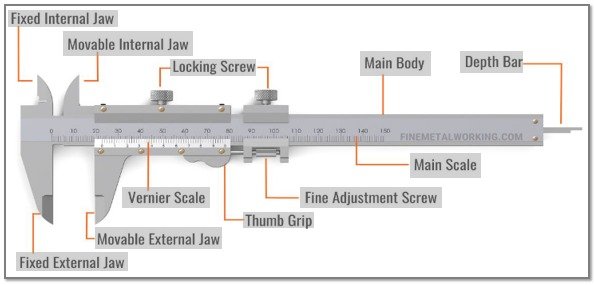

Components:

Here are the main components and features:

Main Scale:

It is a scale that is attached along the entire length of the caliper. The main scale is usually indicated in millimeters (mm) or inches (in) and gives the main indication of the measurement.

Vernier Scale:

It is an additional scale that runs alongside the main scale. It has a more accurate scale than the main scale and allows for more accurate measurements. The vernier scale is marked with divisions corresponding to the proportion of the major divisions.

Jaws:

The gauge has two sets of jaws: one on the top and one on the bottom. The upper jaw is used to measure outer dimensions (for example, outer diameter) and the lower jaw is used to measure inner dimensions (for example, inner diameter).

Sliding Jaw:

The sliding jaw is the moving part of the caliper that holds one end of the object to be measured. It can slide on the main scale and is connected to the vernier.

Fixed Jaw:

The fixed jaw is the fixed part of the caliper that holds the other end of the object to be measured. It is attached to the main body of the caliper and does not move during measurements.

Depth Sensor:

Some calipers have a depth sensor or depth bar on the other end of the jaws. This part measures depth, which is the distance from an edge to a notch. Wheel: Some modern pliers have an adjustment wheel on the slide jaw. The wheel allows fine adjustment of the position of the sliding jaws, enabling accurate measurements without manual movement.

Depth Gauge:

A depth gauge may also have a depth gauge attached to the lower jaw. This is a rod-shaped extension that allows you to measure the depth of holes or notches.

Locking Screw:

A locking screw is provided to lock the vernier in the desired position. This prevents accidental movement of the vernier scale during measurement.

Zero Error Adjustment:

Some vernier calipers have a zero error adjustment feature. This allows for correcting any discrepancies or misalignment between the zero marking on the main scale and the zero marking on the vernier scale, ensuring accurate measurements.

Working:

When using a vernier caliper, it is necessary to close the jaws around the object to be measured and read the indications of the main scale and the vernier scale. The indication of the main scale is determined by the combined mark on the main scale closest to the zero mark on the vernier scale. The vernier designation is determined by the combined vernier notch, which coincides with the notch on the main scale.

By adding the main scale reading and the vernier scale reading, a very accurate measurement can be obtained. Caliper is commonly used in various fields such as engineering, manufacturing, processing and scientific research where accurate measurement is required.

Least Count:

The smallest value of a caliper is the smallest measurement that can be read or measured with the instrument. It represents the accuracy or precision of a caliber. The smallest score is determined by the graduations on the main scale and vernier scale.

The Formula of Least Count:

The formula for calculating the smallest meter count is:

The smallest number = the value of one major division / the total number of divisions on the vernier scale.

In a typical metric caliper, the main scale is divided into millimeters (mm), and the vernier scale is divided into smaller parts, usually 0.1 mm or 0.02 mm.

Example:

Consider an example:

If the main scale is divided by 1 mm (10 parts) and the vernier scale is divided by 10 parts, then:

The value of one division of the main scale = 1 mm / 10 = 0.1 mm

The total number of divisions on the Vernier scale = 10 divisions.

Minimum amount = 0.1mm / 10 = 0.01mm

Therefore, in this example, the minimum measurement value is 0.01 mm. This means that the caliper can measure with an accuracy of 0.01 mm.

Zero error and zero correction:

In a caliper, zero error refers to the situation where the jaws of the caliper are not perfectly aligned when closed and the scale reads zero. This can lead to an incorrect measurement if not taken into account. Zero error can be either positive or negative.

Positive Zero Error:

When the caliper jaws do not close completely and the measurement scale reads a value greater than zero, it is called a positive zero error. In this case, the zero error value must be subtracted from all measurements taken by the caliper to get a correct reading.

Negative Zero Error:

When the calipers close past the zero mark on the gauge scale, resulting in a reading below zero, this is known as a negative zero error. In this case, a zero error value must be added to measurements taken with a vernier caliper to get a correct reading.

Zero correction, on the other hand, is a process of compensating for zero errors. It involves subtracting or adding a zero error value to the measured value to get the correct reading.

Follow these steps to determine the zero error and zero offset of the caliper:

Fully close the meter jaws and check the scale reading. If zero is not displayed, note the value.

If the scale reading is greater than zero, this indicates a positive zero error. The absolute value of the error is zero.

If the measurement scale reads less than zero, this indicates a negative zero error. The absolute value of the error is zero.

To correct the zero error, subtract the positive zero error value or add the negative zero error value to any subsequent caliper measurements.

Remember it is important to always allow for and correct for zero errors to ensure accurate caliper measurements.

Application:

Calipers are versatile measuring tools commonly used in a variety of fields and applications. Here are some of the main uses for meters:

Mechanical Engineering and Manufacturing:

Vernier calipers are widely used in the mechanical and manufacturing industries for accurate dimensional measurements. They are used to measure the length, diameter, thickness, and depth of various components, ensuring the accuracy of the manufacturing process.

Joinery and Woodworking:

Gauges are used in joinery and woodworking to measure the dimensions of wooden components such as boards, planks, and joints. They help achieve accurate cuts and fillets during the construction and assembly process.

Metalworking and Machining:

In metalworking and machining, gauges are vital for measuring the dimensions of metal parts, including length, diameter, and thickness. They aid in quality control by ensuring that design specifications and tolerances are met.

Scientific Research and Laboratories:

Calipers are used in scientific research and laboratories for accurate measurements in various fields such as physics, chemistry, biology, and materials science. They enable scientists and researchers to accurately measure objects and obtain reliable data.

Automotive:

Calipers are used in the automotive industry to measure components such as engine parts, brake discs, bearings, and other mechanical parts. They ensure correct installation and accurate measurements during production and maintenance.

Jewelry Making:

Jewelers use calipers to measure gemstones, diamonds, and other jewelry components. Accurate caliper measurements help determine the value and quality of jewelry.

Medicine and Dentistry:

In medicine and dentistry, calipers are used to measure anatomy, dental implants, and prosthetic components. They help obtain accurate measurements for treatment planning and ensure a proper fit.

Educational and training purposes:

Calipers are widely used in educational institutions and training programs to teach measurement techniques, precision, and accuracy. They help students and interns develop dimensional measurement skills.

It is important to note that calipers come in different types, such as analog and digital versions, with different levels of accuracy and measurement capabilities. Specific applications and requirements determine the choice of meter for a specific application.

What's Your Reaction?