Galvanometer, principle, design, working

Galvanometer, principle, design, working

Galvanometer, principle, design, working

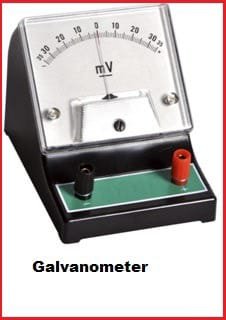

What is galvanometer?

A galvanometer is an instrument used to measure electrical current. It consists of a coil of wire placed in a magnetic field. When an electric current flows through a coil, a force acts on it due to the interaction between the magnetic field and the conductor carrying the current.

Principle of a galvanometer:

The basic principle of a galvanometer is that a current-carrying coil is deflected when current flows through it. The deviation is proportional to the amount of current flowing through the coil. A pointer or a laser beam reflected from a mirror fastened to the coil can be used to see the deflection.

Construction/Design:

The design of a galvanometer usually involves several key components. Here is a general overview of a basic galvanometer design:

Frame:

The galvanometer is housed in a frame or enclosure that provides structural support and protection for the internal components.

Coil:

A galvanometer contains a coil of wire, often called a voice coil or current coil. This coil is usually wound on a lightweight, non-magnetic material, such as a hollow cylindrical shape to minimize interference with the magnetic field.

Suspension system:

The coil is suspended in the frame of the galvanometer by a thin and flexible suspension system such as a torsion fiber or a thin spring. This allows the coil to rotate freely under the influence of magnetic forces.

Magnetic Field:

A permanent magnet or electromagnet creates a magnetic field in the galvanometer. The coil is within this magnetic field, which is mostly uniform and perpendicular to the plane of rotation of the coil.

Pointer:

The pointer is attached to the coil and extends beyond the body of the galvanometer. Movement of the coil rotates the needle, which indicates the strength or direction of the current on a calibrated scale.

Damping Mechanism:

Often a damping mechanism is incorporated to prevent excessive or sustained oscillation of the reel. This mechanism may include a thin air scoop or a fluid-filled chamber that resists the movement of the coil.

Terminal Connections:

The galvanometer has terminal connections to which the electrical current to be measured is applied. These terminals allow current to flow through the coil, creating a magnetic field that interacts with the permanent magnet or electromagnet.

It is important to note that specific construction details may vary between galvanometer types as different designs and modifications are available for specific applications.

Working:

The basic principle of a galvanometer is to convert electrical current into mechanical motion. Here's a step-by-step description of how it works:

Magnetic Field:

A galvanometer has a permanent magnet or electromagnet that creates a magnetic field nearby. This magnetic field is usually uniform and perpendicular to the plane of the coil.

Coil and Swivel:

The coil is made of fine wire wrapped in a compact round shape. It is mounted on a spindle or hinge, which allows it to rotate freely.

Current:

When a small electric current passes through a coil, it acts as a conductor in a magnetic field. According to Ampere's law, a coil of current creates a magnetic field around it.

Magnetic Interaction:

The magnetic field generated by the coil interacts with the external magnetic field of the galvanometer resulting in a torque on the coil. The torque is proportional to the product of the current flowing through the coil and the magnetic field strength.

Coil Deflection:

Torque causes the coil to rotate or deflect, aligned with the direction of the magnetic field.The coil's deflection angle is inversely proportional to the current that passes through it.

Recoil spring:

A coil spring is usually attached to the spool to provide restoring force. The spring creates an opposing torque and tries to return the coil to its original position when no current is flowing through it.

Measurement:

The deflection of the coil is sensed using a scale or pointer that moves in response to the movement of the coil. The variation can be connected to the current flowing through the coil by calibrating the galvanometer.

It is important to note that the galvanometer is often used as a sensitive measuring instrument and is not suitable for direct measurement of large currents. To use the galvanometer for practical applications, it is often incorporated into more complex instruments such as ammeters or voltmeters, where additional components are added to measure the scales and provide the necessary protection.

Adnantages and disadnantages:

The advantages of a galvanometer include the following:

They are not affected by a strong magnetic field.

Accurate and reliable

The scales of these are uniform

The disadvantages of the galvanometer are as follows:

Overloading can ruin any kind of galvanometer.

A change in temperature changes the recovery torque.

We cannot simply change the recovery moment.

They cannot be used to measure alternating current.

Applications:

Applications of this include.

It is used to detect the direction of current flow in the circuit and also determines the zero point.

Used to determine current.

This allows us to determine the voltage between two points.

They are used in control systems, laser engraving, laser TVs, laser sintering, laser displays, etc.

They are used in CD/DVD players and hard drives to control the position of the main servos.

They are used in a film camera to make photoresist measurements in measuring mechanisms.

What's Your Reaction?